I do a lot of projection installations, in unique locations, usually with about zero setup time. When I looked into buying a professional 10’x7’ “fast-fold†screen, I was blown away by how much they cost. Instead, I decided to design my own, using easy to find materials.

I do a lot of projection installations, in unique locations, usually with about zero setup time. When I looked into buying a professional 10’x7’ “fast-fold†screen, I was blown away by how much they cost. Instead, I decided to design my own, using easy to find materials.

The Challenge:

1. Fast to set-up

2. Fits in a cab

3. Front or rear projection

4. Affordable

Tools:

Sewing machine

Scissors

Pipe cutter ($20 most hardware stores)

Materials:

Aluminum Electrical Conduit ($11 for 10’ pole)

4 Aluminum Elbow Joints (â€Speed-Rail†brand, 1†dia. roughly $10 each)

Front Projection Material (Dazian in NJ, $110 for 9’x7’)

OR Rear Projection Material (Dazian again, $170 for 9’x7’)

Lycra Fabric (strong, not thin stuff), stretches in both directions (most fabric stores, $16 for 3 yards)

Instructions:

1. Once you have all the parts, lay out the screen material.

2. Cut out the stretchy lycra material 12†wide by 7′. You’ll need two strips this size. Its what keeps the screen tight to the frame.

3. Put your sewing machine on wheels. I used a 1’ sq. piece of pegboard with small wheels attached. Its a lot easier to move the sewing machine than the whole screen and lycra roll.

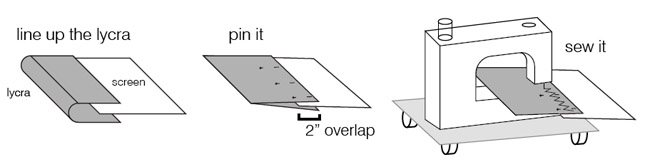

4. Pin the lycra to the screen, with about 2†overlap on the front and back, sandwiching the screen material between lycra. You’re making a sleeve for a pole to go through, tent-style.

5.Wheel the sewing machine along this seam, with a very wide zig-zag stitch. Don’t over-sew, as the screen material has a tendency to rip when there’s too much stitching. Thicker thread is better for the same reason. Again, fewer stitches is stronger, as the vinyl can rip easier with a lot of holes in it from too many stitches

6. Cut the aluminum conduit. Allow for space to stretch the lycra. Poles should be about 6†wider than your actual material (3″ per side). This is a very tricky step, and may require cutting the pipes to allow the screen to stretch enough, but not too much, on the horizontal. Cut them down in small increments until the screen is held tightly by the lycra.

That’s it!

To make the screen cab-ready, the poles have to be cut down to 5’ lengths. Luckily, aluminum conduit comes with couplers and screw ends, and the 10’ poles can simply be cut in half. The 7’ poles cut down as well, but you have to cut out the middle 3’, so you can keep both ends.

If you need it to be free-standing, cut some small poles and put them perpindicular to the screen in the elbow joints. If you need it hung up, use an eyehook in the speedrail joint instead of the allen wrench screw. I often will get rid of all the allen screws, replacing them with eye hook screws, so I don’t have to track down an allen wrench at 6 in the morning when tearing down…sigh. We learn….

This screen design comes from lots of trial and error. It looks very professional, but costs so much less than a 9′ x 7′ pro screen. And, because all the parts are pretty easy to find, its simple to adapt the frame to different screen sizes.

Here’s some photos of a 12’7′ rear projection screen for the Zero Film festival we built with the method above.